Mobile Shrink Column Turbopack the heat tools alternative

-

Maximum retraction height80cm120cm160cm200cm240cm320cm

-

Energy developed75kW110kW143kW177kW210kW280kW

-

Consumption at 100%5,48kg/h8kg/h10,35kg/h12,79kg/h15kg/h20kg/h

-

Adjustable pressure1,5 to 2,5 bars1,5 to 2,5 bars1,5 to 2,5 bars1,5 to 2,5 bars1,5 to 2,5 bars1,5 to 2,5 bars

-

Gas usedPropanePropanePropanePropanePropanePropane

-

Empty weight84kg94kg102kg112kg121kg140kg

-

Passage around pallet140cm140cm140cm140cm140cm140cm

-

Visor optionNoNoYesYesYesNo

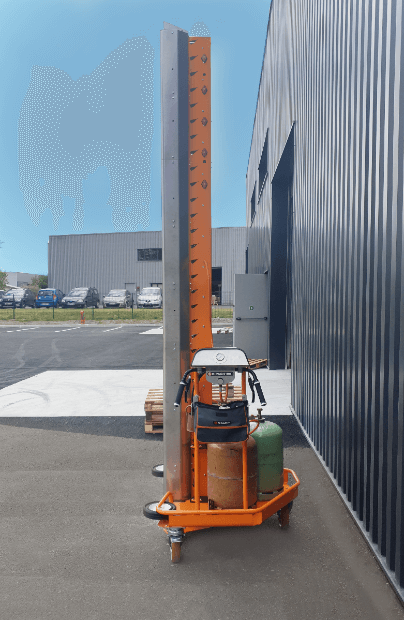

Autonomy and mobility, the advantages of a mobile packaging shrink station

The Turbopack is a heat shrink column installed on a trolley that is easily moved thanks to its pivoting wheel system. This allows the operator to shrink at any point in the shipping area, thus avoiding the movement of unstable loads.

More efficiency thanks to its power and speed

Its unique design allows for a strong hot air flow for efficiency even on thick films. 50 seconds are enough to shrink a pallet (euro type) regardless of the height (upper limit at 3.2 m).

The only adjustment required is to close the valve to set the height to be shrunk. Adaptation to the load to be retracted is therefore quick and easy. There is no need for programming, time-consuming handling or complex maintenance.

Economical and flexible for an unmatched price/performance ratio

The Turbopack can carry up to 3 gas cylinders (13 kg). With more than 60 pallets shrunk per cylinder, the autonomy and low consumption are real assets for your shrinkage station.

There is no limitation of length or width of the load (unlike frames or ovens) and up to 3.20 m high. It is a real advantage for very long pallets and shrinkage of different sized pallets. In addition, a visor option is available for models from 1.6 to 2.4m